Project Management

We take a comprehensive and customized approach. Our commitment goes far beyond a simple commercial transaction. We are dedicated to delivering a quality control solution that perfectly meets your production needs, while offering ongoing support. This ensures that your Rovi-tecH system remains efficient and aligned with your long-term requirements.

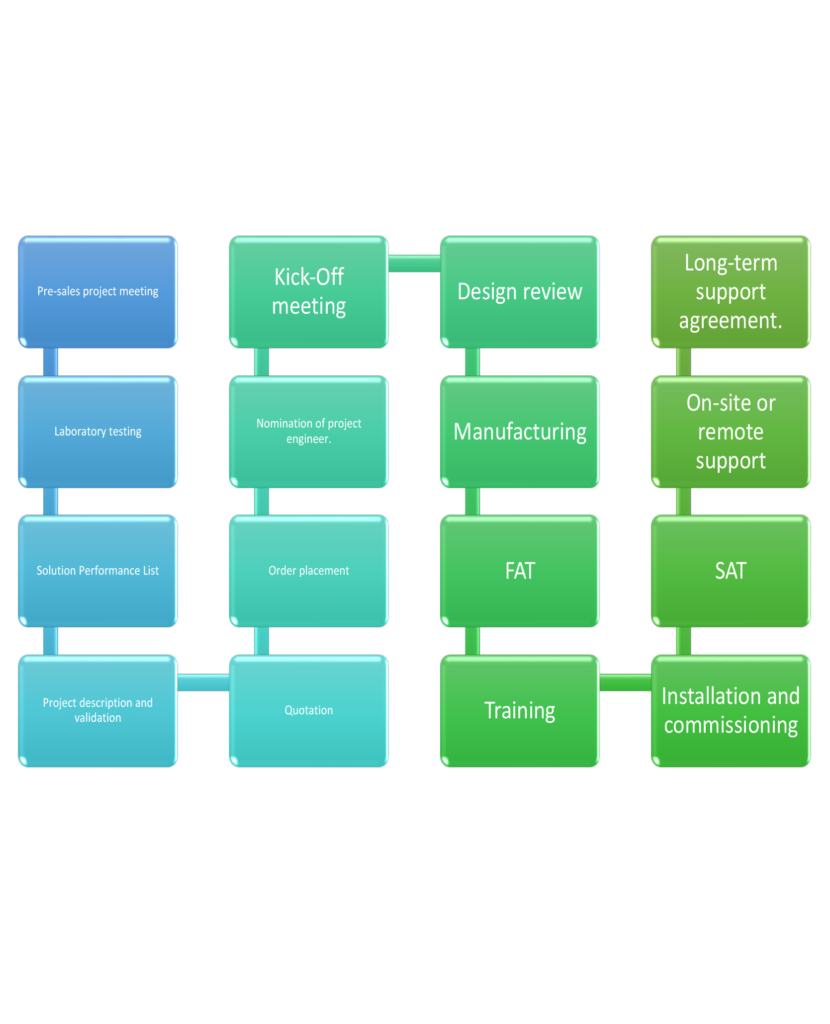

To achieve this goal, we manage our projects through clearly defined procedures. The diagram below outlines the steps that can be activated as part of your quality control project on production lines.

- Preliminary project study

- Laboratory testing

- Development of the machine performance report

- Price offer

- Order placement

- Appointment of the project engineer

- Project kick-off meeting

- Drafting of the functional analysis

- Validation of the functional analysis

- Production

- Factory Acceptance Testing (FAT) in our workshops

- Training of your teams

- Installation and commissioning

- Site Acceptance Testing (SAT)

- Follow-up of the installation by our teams

- Support and maintenance

Each of these steps is essential to ensuring the success of your quality control system project. They reflect our commitment to delivering customized and high-performance solutions, thereby optimizing your production and ensuring the safety of your industrial processes.