Technologies

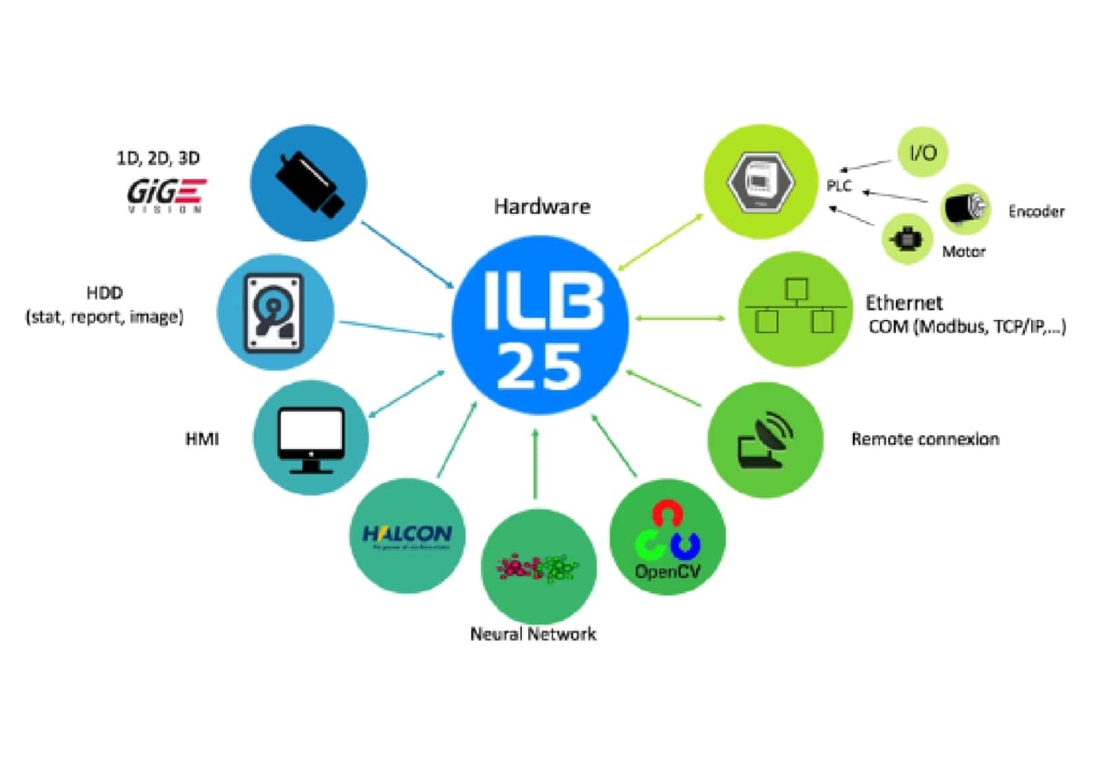

Rovi-tecH’s ILB-25: The ultimate platform for quality control through image and signal processing.

Our cutting-edge quality control system leverages the advanced ILB-25 technology, a fully customizable platform that strikes the perfect balance between operational requirements, technological performance, and cost-efficiency.

Key features of the ILB-25 include:

- Built on a durable industrial PC;

- Uses high-speed Ethernet-connected digital cameras;

- Flexibele integratie van 1D-, 2D- en 3D-camera’s, afgestemd op de specifieke toepassing;

- Offers flexibility to integrate 1D, 2D, and 3D camera technologies, tailored to each specific

application; - Enables vector-based image analysis, a proprietary Rovi-tecH technology;

- Integrates advanced learning capabilities through a neural correlator, an innovative Rovi-

tecH development; - Comes with an extensive library of vision tools, ensuring high performance, flexibility, and

scalability to meet evolving demands; - Applicable across various domains: sorting, metrology, reading, identification, and more.

The ILB-25 stands out as the ideal solution for tackling challenges such as detecting subtle or complex defects, frequently encountered in industries like food or pharmaceuticals, where product variability complicates standardization. This technology enables the system to learn and analyze inspection data efficiently, surpassing the capabilities of traditional algorithms.

By integrating ILB-25 technology, our inspection systems enhance adaptability, reliability, and user-friendliness, breaking through traditional barriers to deliver maximum precision and efficiency in product inspection.